How we will change lithium Recycling in Austrlaia

A large focus of Sustainable Lithium Cells Australia Pty Ltd is reducing the amount of consumer household battery product, particularly those with embedded batteries, from entering waste bins.

Using a straight forward, openly replicable approach, we can incentivise businesses to take responsibility for encouraging consumers to return EOL products to consolidation points for us to collect, most obviously, the place where they were purchased from. We do this with financial, SEC and RnD benefits.

The general recycling industry and government consensus is that product suppliers should take responsibility/stewardship for the safe disposal of products they bring to market. But suppliers are de-incentivized to do this due to prohibitive additional costs, leaving the disposal fees in the hands of their unaware and unwilling consumers (often with return and recycling information hidden in the small print).

Our company is experienced in the efficient and cost positive dismantling and resource recovery of lithium batteries and the products powered by them. The technology required for this is not advanced and does not need to be, however, it does require experience in methodologies, custom tooling and understanding various product designs. These are the skills we have been honing since 2021, which have allowed us to be the only providers of completely free or otherwise the most discounted recycling providers to many businesses in Australia that have already taken it upon themselves to reconsolidate (often cheaply through reverse logistics) their EOL products.

What is in it for the businesses? Through our systematic dismantling we can provide RnD feedback on batch faults when products are dismantled and tested, and through our partner Substation33, we can use the recovered recourses to power and fund social enterprise initiatives such as electronic lighting, signage and solar power storage for remote communities.

We wish to bring this methodology into the B-Cycle program, to showcase implementing embedded product into the scheme, we can prove how the cost of disposal for embedded products can sustainably be passed onto the consumer for a negligible amount, whilst simultaneously encouraging customer traffic back into the store of origin when they are due for a product replacement or upgrade.

The highest benefit of this model is that it will severely reduce the burden on other re-active measures for lithium disposal dangers such as Detection Systems and fire response systems in general waste streams. It will also make product suppliers and retailers incentivized to provide informative recycling awareness as an added side effect.

There is an additional community benefit through the production of upcycled products, particularly the ability to create extremely affordable second life solar storage products through our social enterprise partners PowerWells and Substation33 who also employee out of work and at risk individuals for upskilling, e-waste resource recovery and second life lithium battery manufacturing.

To scale this business model to a noticeably impactful level will require the co-operation of other businesses to willingly advertise their ability to reclaim their EOL products to in turn allow confidence in our ability to scale up our facility and collection networks to receive this predictable available for recycling supply. We need industry support and awareness of our services. Our bootstrapped start-up is experienced with working on the coal-face of dismantling and recycling EOL products, by participating in long term supply contracts there are significant financial and SEG benefits. Our current business model is a gateway and role model for how lithium battery recycling does not need to be costly to individuals or businesses, and is a stepping stone to the the 95%+ recycling rates seen in lead-acid battery recycling where people are paid for their scrap batteries.

What Happens to Retired Batteries

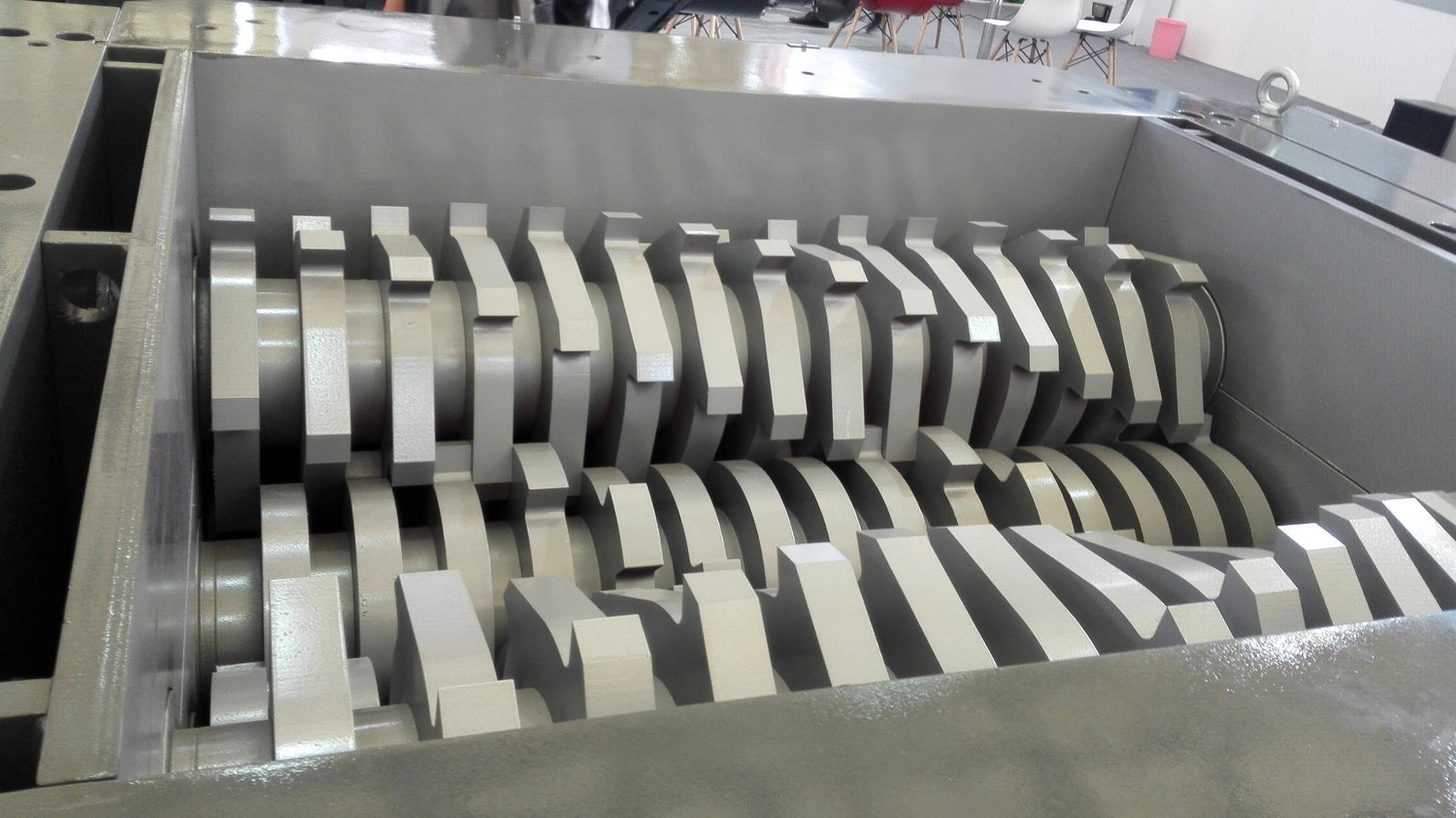

In Australia, lithium ion batteries that are put into commercial recycling streams will all eventually find themselves being shredded for their raw material worth.

The actual green house gas emission cost to produce a lithium ion cell varies between countries of manufacture but the process is described in this scientific report.

How we plan to do things differently:

We aim to allow more of the potential lifespan of batteries to be accessed through a second life scheme, thus preventing the resources of battery production being wasted and emissions being released, when batteries retire or are used in faulty equipment.

Fill out the form below to organise a collection: